Power Calculation and Test Conditions for Monocrystalline Silicon Solar Cells

Power Calculation and Test Conditions for Monocrystalline Silicon Solar Cells

Solar cells mainly include crystalline silicon cells and thin film cells, and their respective characteristics determine their irreplaceable status in different applications.

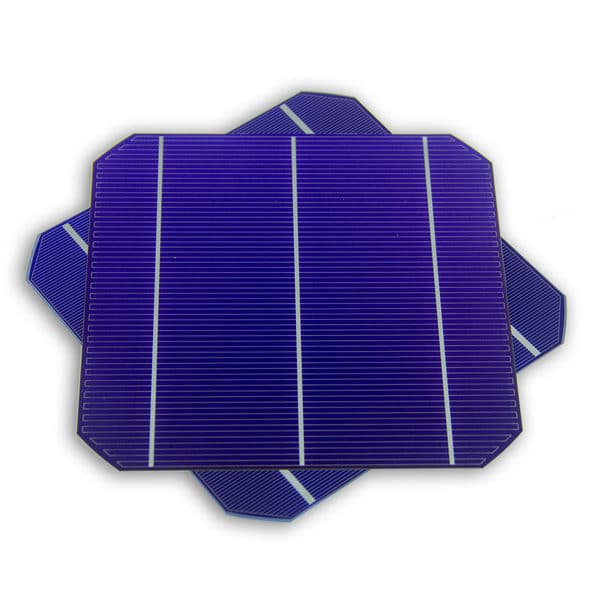

This solar cell uses high-purity monocrystalline silicon rods as raw materials, and the purity requirement is 99.999%. In order to reduce production costs, solar cells for ground applications use solar-grade monocrystalline silicon rods, and the material performance indicators have been relaxed. Some can also use the head and tail materials and waste single crystal silicon materials processed by semiconductor devices, and make single crystal silicon rods dedicated to solar cells after redrawing. Cut the monocrystalline silicon rod into slices, generally with a thickness of about 175 μm. After forming, polishing, cleaning and other processes, silicon wafers are made into raw silicon wafers to be processed.

Power Calculations for Monocrystalline Silicon Solar Cells

The solar AC power generation system is composed of solar panels, charge controllers, inverters and batteries; the solar DC power generation system does not include the inverter. In order to make the solar power generation system provide enough power for the load, it is necessary to select the components reasonably according to the power of the electrical appliances. Let’s take 100W output power and use it for 6 hours a day as an example to introduce the calculation method:

1. First, calculate the watt-hours consumed per day (including the loss of the inverter): If the conversion efficiency of the inverter is 90%, then when the output power is 100W, the actual required output power should be 100W/90% = 111W; if it is used for 5 hours a day, the power consumption is 111W*5 hours=555Wh.

2. Calculation of solar panels: Based on the daily effective sunshine time of 6 hours, and considering the charging efficiency and loss during charging, the output power of solar panels should be 555Wh/6h/70%=130W. Among them, 70% is the actual power used by the solar panel during the charging process.

Test conditions for monocrystalline silicon solar cells

1. Since the output power of solar modules depends on factors such as solar irradiance and solar cell temperature, the measurement of solar cell modules is carried out under standard conditions (STC), which are defined as: air quality AM1.5, light intensity 1000W/m2 , temperature 25°C.

2. Under this condition, the maximum power output by the solar cell module is called the peak power. In many cases, the peak power of the module is usually measured by a solar simulator. The main factors affecting the output performance of solar cell modules are load impedance, sunlight intensity, temperature, shadow and so on.

Monocrystalline silicon solar cells are solar cells made of high-purity monocrystalline silicon rods, and are currently the fastest-developing solar cells. Its structure and production process have been finalized, and the products have been widely used in space and ground.