Hydrogen Fuel Cell Stack Dispensing Process Introduction

Hydrogen Fuel Cell Stack Dispensing Process Introduction

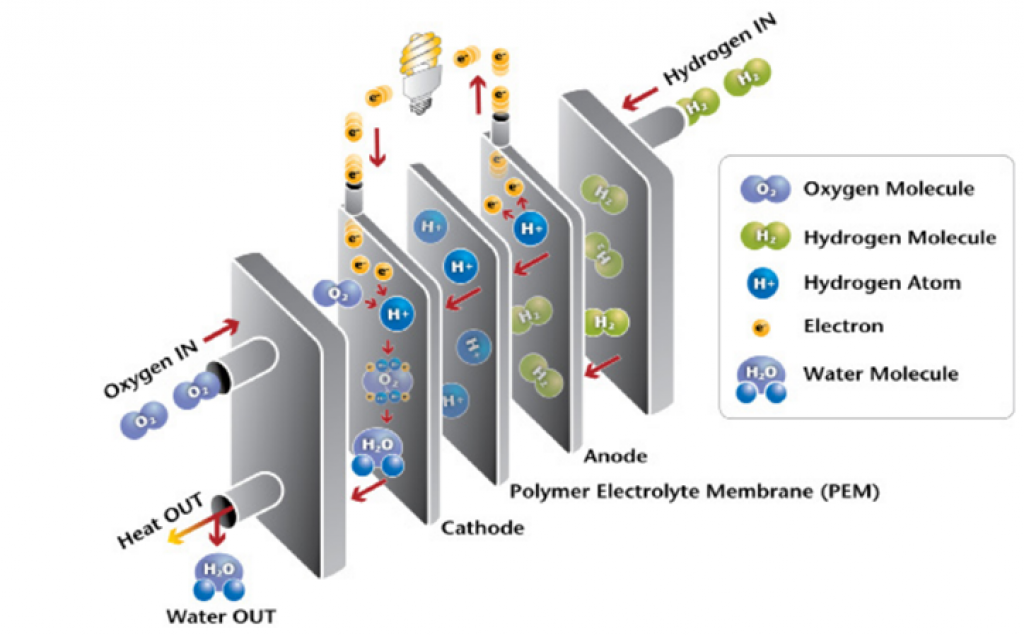

Regardless of the supply of hydrogen fuel, hydrogen fuel is a clean energy that only produces water, and the ultimate form in the future is likely to be a hydrogen fuel cell solution. Domestic and foreign automakers and domestic OEMs have followed suit, investing technology and manpower in the R&D and trial production of hydrogen fuel vehicles. Everyone is welcome to identify the QR code and join the WeChat group and address book through the QR code of the official account.

Today we will sort out the dispensing process in the assembly process of hydrogen fuel cell stack (Hydrogen Fuel Cell Stack).

The key components of hydrogen fuel stacks are: hydrogen fuel bipolar plate, proton exchange membrane + electrode, current collector plate, rubber seal/sealing rubber ring, other insulating plates, fasteners, and shells are general components, and the above components together form hydrogen fuel stack.

Among the above core components, the glue dispensing process (also using a sealing ring) is the core sealing process, which affects the airtightness and safety of the stack. Therefore, parameters such as the uniformity of glue dispensing, the width and height of glue are very important.

In the hydrogen fuel stack, the dispensing process mainly includes the following parts: graphite bipolar plate micropore filling, graphite bipolar plate and composite bipolar plate waterway bonding, bipolar plate gas path sealing, MEA frame bonding and electric There are five types of shell sealants.

After the dispensing is completed, the dispensing process needs to be verified for the glue path. Through the 2D/3D line laser or line spectrum confocal detection software, the defects of the glue path and glue width can be detected, and the dispensing process can be improved and optimized in time to improve the production efficiency. Efficiency and yield, reduce labor costs.

Glue road detection software includes visual detection, 3D line laser detection, 3D line spectral confocal detection, etc., which can be flexibly selected according to project needs (products, detection angles, glue conditions, upper and lower processes, etc.).

Dispensing machine is a high-end equipment that realizes mechanized production. It is also called sizing, gluing, gluing, dripping, spraying, etc. The product has some functions such as bonding, insulation, fixing, and smooth surface. The motion trajectory can also be programmed independently according to production needs, and it can be used for dispensing on any non-plane. It can not only improve the consistency of dispensing, reduce material waste, but also Improve work efficiency and quality, and realize high-end equipment for mechanized production.