Blog

Blog

Energy Storage Cell Testing: Appearance, Size, Safety, and Environmental Standards

Published by Dawnice, February 18, 2025

The Appearance Judgment Standard and Testing Standard of Energy Storage Battery Cells

The appearance judgment standard and testing standard of energy storage battery cells are important links to ensure the quality and safety of the battery cell. Appearance judgment standards and testing standards for energy storage batteries are a series of specifications established to ensure the quality and safety of the product. These standards are usually set internally by the manufacturer or follow industry standards, national standards, or even international standards.

I. Appearance Determination Standards

-

Surface Defects

The surface of the electric core should be flat, with no damage, no deformation. Check whether there are scratches, pits, bumps, cracks, and other defects. -

Color Consistency

The color of the electric core should be uniform, with no obvious color differences. -

Size Consistency

The size of the core should be within the specified tolerance. -

Condition of Terminals

The terminals should be free of oxidation and corrosion, and should be firmly installed. -

Marking Clarity

The marking labels and printed information (such as model number, specification, production date, manufacturer, etc.) on the electric core should be clear and accurate, facilitating user identification and traceability. -

No Leakage Phenomenon

The electric core should be free of electrolyte leakage to prevent the electrolyte from causing corrosion or damage to the surrounding environment and equipment.

II. Safety Performance Tests

-

Cycle Life Test

Evaluate the performance stability and life of the electric core under different cycle times through repeated charging and discharging cycles. -

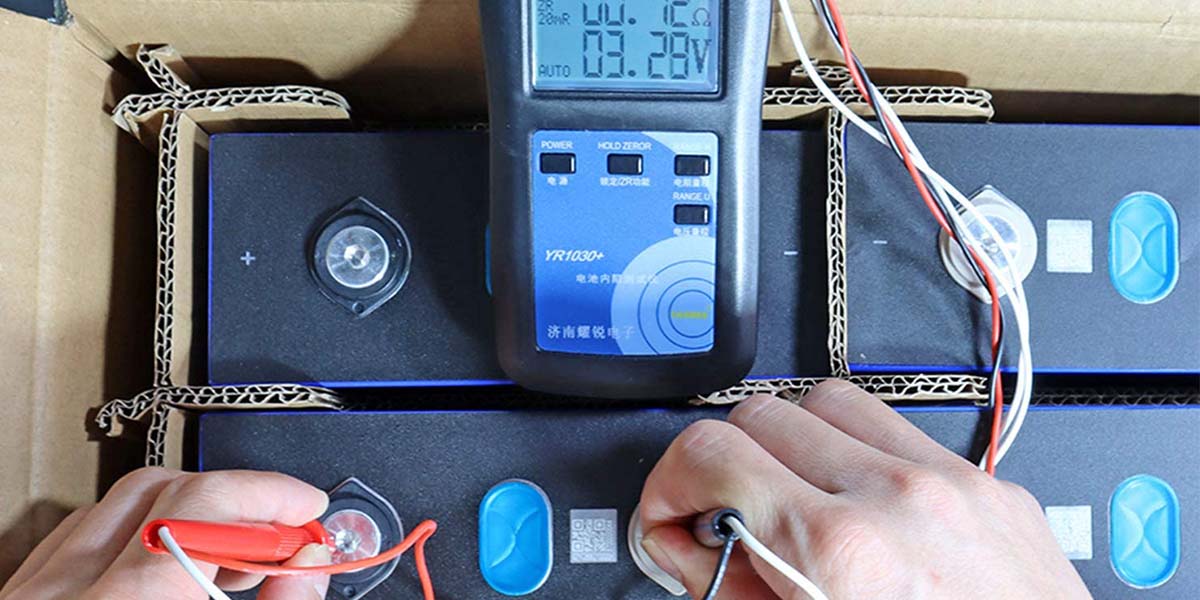

Electrical Performance Test

This includes:- Initial charging and discharging energy test

- Multiplier charging and discharging performance test

- High temperature charging and discharging performance test

- Low temperature charging and discharging performance test

-

Other Special Tests

Such as:- Self-discharge test

- Battery balance test

- SOC/SOH estimation, etc. To comprehensively evaluate the performance and status of the battery cell.

-

Short-circuit Test

Test the response and safety performance of the battery cell under short-circuit conditions. -

Overcharge and Overdischarge Test

Test the performance and safety performance of the battery cell in overcharge and overdischarge situations. -

Thermal Runaway Test

Evaluates the safety performance of the battery cell under extreme temperature conditions to prevent safety accidents caused by thermal runaway. -

Other Safety Tests

Such as puncture test, extrusion test, etc., to simulate the safety performance of battery cells under extreme conditions.

III. Environmental Adaptability Tests

-

Temperature Performance Test

Test the performance of the battery cell at different temperatures, including capacity, internal resistance, and charging/discharging efficiency. -

Safety Performance Test

Includes tests like:- Over-charging test

- Over-discharging test

- Short-circuit test

- Extrusion test

- Drop test

- Low air pressure test

- Heating test

- Thermal runaway test, etc.

-

Environmental Adaptability Test

Includes:- Energy retention and recovery ability test

- Storage performance test

- Cycle performance test, etc.

-

Humidity Test

Evaluate the performance of the battery cell in a humid environment. -

Vibration and Shock Test

Test the stability and reliability of the battery cell under vibration and shock conditions. -

Cycle Life Test

Evaluate the performance stability and life of the battery cell under different cycle times by repeated charging and discharging cycles. -

Other Specialized Tests

Such as self-discharge test, battery balance test, SOC/SOH estimation, etc., to comprehensively assess the performance and status of the battery cells. -

Square Cell Puncture Test

IV. Domestic and International Standard References

-

GB/T 36276-2023

Applicable to the design, manufacture, testing, inspection, operation, maintenance, and overhaul of lithium-ion batteries for power storage. -

IEC 62660 Series

Standards related to lithium-ion batteries for electric vehicles. -

UL 1642

Safety standards for lithium-ion batteries for portable devices.

When carrying out the testing of energy storage battery cells, the relevant standards and norms should be strictly followed to ensure that each testing process meets the requirements. Meanwhile, testing equipment and tools should be calibrated and verified to ensure the accuracy and reliability of the test results. In addition, test results should be recorded and archived in a timely manner for subsequent tracking and analysis.