Hot Spot Effect and Countermeasures of Thin Film Photovoltaic Modules

Hot Spot Effect and Countermeasures of Thin Film Photovoltaic Modules

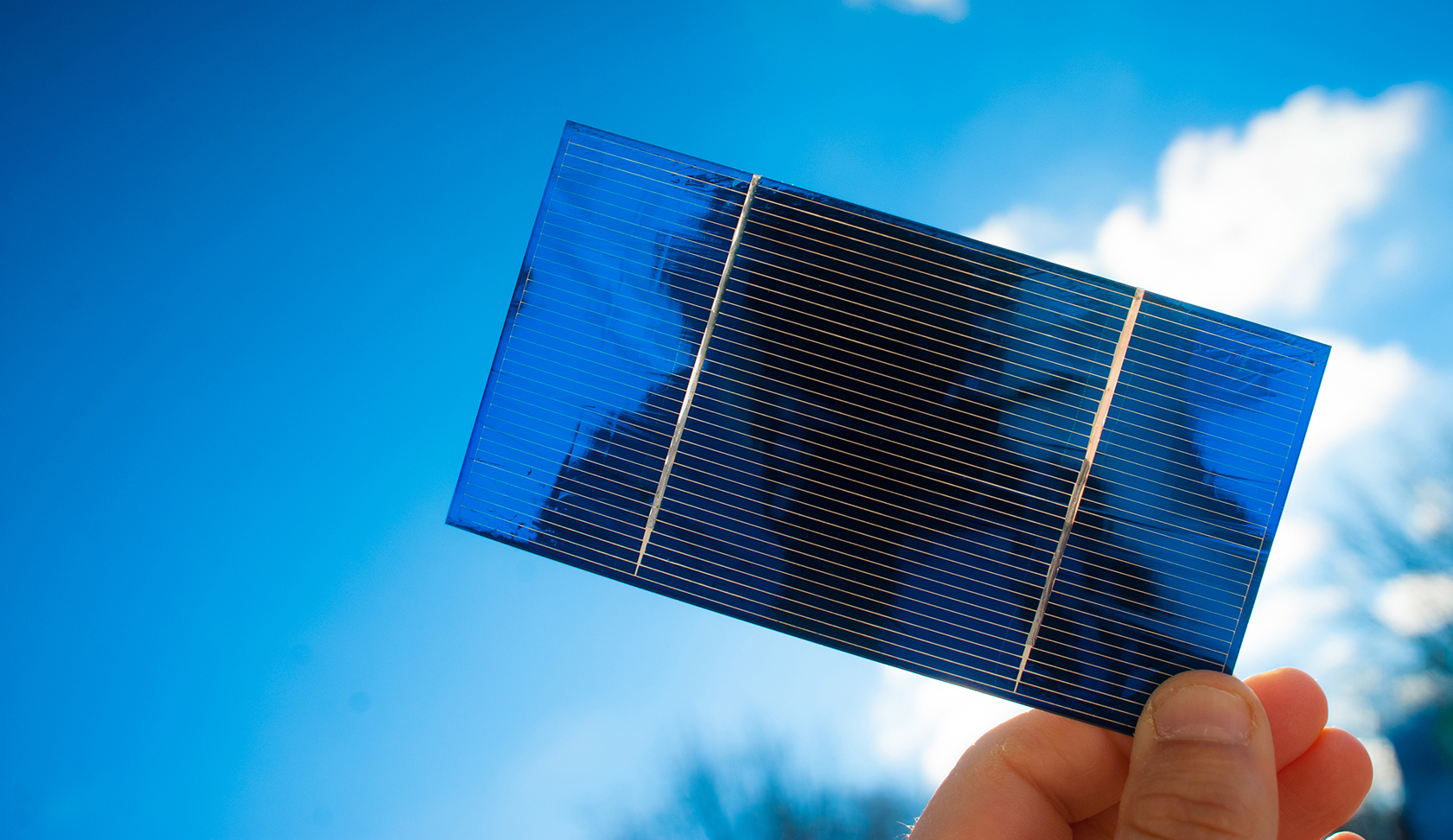

With the rapid development of science and technology, photovoltaic power generation technology has been widely used at home and abroad. Its application forms are various and its application places are widely distributed. Building integration, photovoltaic street lights, etc. In these places, it is inevitable that buildings, tree shade, chimneys, dust, clouds, etc. will block the solar cell modules. Therefore, people are concerned about how much this kind of situation affects the power generation efficiency of solar cells, and how to solve it?

In practical applications, solar cells are generally connected in series or in parallel by multiple battery components to obtain the desired voltage or current. In order to achieve high photoelectric conversion efficiency, each cell in the cell assembly must have similar characteristics. During use, one or a group of batteries may not match, such as: cracks, internal connection failure or shading, etc., causing its characteristics to be inconsistent with the whole. Under reasonable lighting conditions, the shaded photovoltaic cell in a series branch will change from a power generation unit to a power consumption unit. The shaded photovoltaic cell not only does not contribute to the output of the module, but also consumes the power generated by other batteries. It will generate heat when it is hot, which is the hot spot effect.

Compared with crystalline silicon, the film thickness of amorphous silicon thin-film battery components is relatively uniform throughout the component, and the current matching of multiple sub-cells is good, and there will be no cracks or hidden cracks in crystalline silicon components. Through excellent production technology And the amorphous silicon photovoltaic module made of strict quality control system, there is almost no problem of internal link failure of each sub-cell in the thin film module. In addition, for crystalline silicon solar cells, a small shading can cause a large power loss, resulting in excessive temperature of the components, which will burn out the components and even cause a major fire; but the current density of amorphous silicon thin film cells is small, and shadow shading is very important Thin-film batteries will also have an impact, but the impact is much smaller than that of crystalline silicon batteries.

For the hot spot effect of thin film photovoltaic products, the International Electrotechnical Commission has formulated strict certification test standards, and the products must withstand the test of the hot spot effect under extremely harsh conditions. After the thin-film photovoltaic module has passed the hot spot durability test, the visual inspection is first carried out, and any cracks, bubbles or delamination are recorded or photographed. If serious appearance defects specified in the standard are found, such as: broken, cracked, bent, irregular or damaged outer surface; any thin film layer in the effective working area of the module has more than 10% of the cell area, visible corrosion, Formation of continuous bubbles or delamination between the edge of the component and any part of the circuit, etc., loss of mechanical integrity, resulting in the installation or operation of the component being affected, is considered unqualified. If there are appearance defects but do not belong to the serious appearance defects mentioned above, such as: any film layer in the effective working area of the component has voids and visible corrosion, output wires have visible corrosion, etc., take pictures and record them; if in other subsequent tests If the experiment has no effect, it is considered that the thin-film photovoltaic module has passed the hot spot effect test. If it is affected, two other modules are selected to re-do the hot spot effect test. In addition, the attenuation of the maximum output power of the module under standard test conditions cannot exceed 5% of that before the test; the insulation resistance should meet the same requirements of the initial test.

Customers can rest assured that at present, many domestic thin-film module manufacturers, including Pule New Energy, have passed the most authoritative and strictest product performance and safety certification in the world. It should be noted that during the design, construction and grid-connected use of photovoltaic power stations, the impact of shading on photovoltaic power stations and photovoltaic systems should be fully considered. The impact of the photovoltaic system is reduced to a minimum.